|

|

|||

|

|

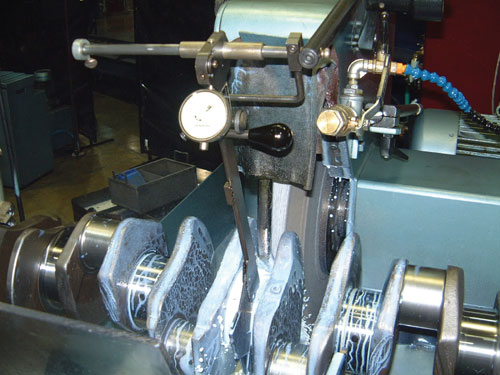

Home > Our Clients > Case Studies > Setup Reduction SETUP REDUCTIONA Case Study of Crankshaft Grinding Setup reduction is one of the most used and most valuable Lean tools. Shorter setup times allow the production process to achieve greater flexibility, maximize machine capacity with little or no additional cost, and shrink lead times. A diesel engine remanufacturer determined that crankshaft grinding, a key step in the engine rebuilding process, was not meeting its TAKT time requirement. Actual grinding time on each crankshaft was well below TAKT time. However, overall cycle time (including setup time) exceeded TAKT time by 30 minutes. To correct this deficiency, the company had 2 clear choices:

purchase another crankshaft grinding machine, or reduce the setup

times by at least 30 minutes.

Organize the Project With TCA's guidance, the remanufacturer formed a setup reduction team and charged them with these objectives:

Train the Team After bringing together a team of machine operators, maintenance technicians, and engineering support personnel, our first step was to teach them the principles and techniques used in setup reduction. In a short half-day session, TCA delivered the training and made initial assignments for collecting data about the current crankshaft grinding setup. Analyze the Setup One of the best ways to analyze a setup process is to videotape the entire setup. Using this technique, the setup reduction team identified each of the steps in the actual setup and recorded the times required. Distinguish Internal and External Elements Shifting internal activities to external activities is the first key concept in setup reduction. In many cases, as much as 50% of the time consumed in a typical setup can be removed by shifting internal setup element tasks to external.

After identifying the elements of the setup, the team began to examine each element to determine whether it could be made into an external setup element. In this case, the team was able to identify only 3 elements that could be accomplished externally. These elements reduced the internal setup time by 18 minutes. Streamline Internal Elements The next step was to make additional reductions by streamlining the remaining internal items. After thorough evaluation, the team determined to implement additional improvement ideas that further reduced internal setup times by 25 minutes. Finally, the team continued to work the remaining steps in the setup reduction process. In further analysis, the team noted that several elements of the grinding process might be eligible for streamlining. Rough estimates of cycle time reduction from these three ideas may total another 10 minutes. Implement Changes After following the remaining steps in the process, the team began the process of implementing their ideas. Once the improvements were made, a setup reduction performance measurement board was constructed and placed next to the machine to track setup time performance over the next few weeks. This assured that improved methods soon become habit and reductions become permanent. Final results of the setup reduction project on the crankshaft grinding process yielded net savings of 43 minutes, exceeding the original goal by nearly 50%. The setup in this example — that of changing from one style of crankshaft to another — was only one of a number performed in the crankshaft grinding process. Others such as repositioning the crankshaft during the grinding process, occurred much more frequently. The same setup reduction process was applied to these other setups with similar results. Results The total benefit of these setup reduction improvements was much greater than originally hoped for. The training, hands-on application, and team approach to setup reduction exceeded the initial objectives and has completely eliminated a long-term bottleneck in the engine rebuilding process. The company is currently applying the same setup reduction techniques to other operations and expects substantial improvement in overall flexibility, cost savings, and increased responsiveness to changing demand.

|

||

|

|